« Watkins Glen | Main | Sound Testing »

September 23, 2006

Welding valve cover pockets

Since I built the new engine, there have always been oil leaks coming from the valve covers. These AFR 210 heads are perimiter bolt, while the old L98 had centerbolt valve covers that never leaked. I initially had some gorgeous sheet metal valve covers, but they hit the turbos severely, so they were sold to Rick, for his mean yellow 427 Camaro. I then acquired some solid cast aluminum valve covers from David Tuschoff at Thunder Racing, but they also hit the turbos. The only ones that would clear were the cheapest, flimsiest stamped steel valve covers. Which leak. Even with The Right Stuff RTV that seals anything. I was fed up with the mess, and finally took the die grinder to the cast aluminum valve covers, and cut out sections. Quite a bit was necessary for the drivers side, but the passenger side barely hit. There was a concern about the heat warping the valve covers, but a friend of mine from my days at Mallory (Jeff Diener) suggested welding them in a baking pan of water, to act as a heat sink.

Getting a fresh edge for the TIG welder:

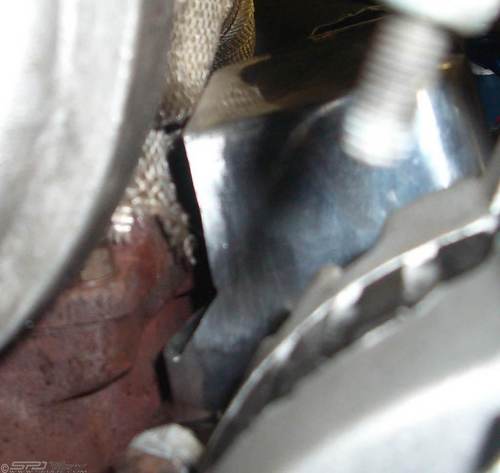

Checking clearance against the passenger turbo:

Posted by Z28tt at September 23, 2006 10:53 PM