« July 2006 | Main | October 2006 »

September 23, 2006

Welding valve cover pockets

Since I built the new engine, there have always been oil leaks coming from the valve covers. These AFR 210 heads are perimiter bolt, while the old L98 had centerbolt valve covers that never leaked. I initially had some gorgeous sheet metal valve covers, but they hit the turbos severely, so they were sold to Rick, for his mean yellow 427 Camaro. I then acquired some solid cast aluminum valve covers from David Tuschoff at Thunder Racing, but they also hit the turbos. The only ones that would clear were the cheapest, flimsiest stamped steel valve covers. Which leak. Even with The Right Stuff RTV that seals anything. I was fed up with the mess, and finally took the die grinder to the cast aluminum valve covers, and cut out sections. Quite a bit was necessary for the drivers side, but the passenger side barely hit. There was a concern about the heat warping the valve covers, but a friend of mine from my days at Mallory (Jeff Diener) suggested welding them in a baking pan of water, to act as a heat sink.

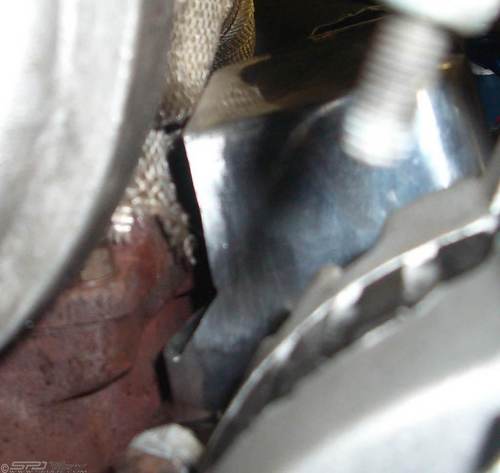

Getting a fresh edge for the TIG welder:

Checking clearance against the passenger turbo:

Posted by Z28tt at 10:53 PM | Comments (0)

September 20, 2006

Watkins Glen

Just an old picture I found from Watkins Glen, in 2001...

Posted by Z28tt at 10:29 AM | Comments (0)

September 13, 2006

Air Compressor hard lines

On the way down to Delaware to pick up a Southbend CL145B lathe, I stopped by Fred Breitweiser's, in NJ. He donated a spare roll of 1" Type K copper tubing to the garage fund. I attempted to give him some cash to support his random shed projects, but he's just going to hold my little MIG hostage instead! :) Spec's on the copper tubing are:

Cerro Type K (high pressure)

NSF 61

.065" wall / .995" ID / 1.125" OD

665 max psi @ 70 degF.

Temp Range -425 to +400 degF

I'll have 130" against the wall, a 130" drop along the ceiling line

I'll have a 6' rise to the rafters from the compressor, 350" along the ceiling, sloped down, and 130" along the workbench wall to the Harbor Freight air dryer/regulator and 50' 3/8" hose reel I picked up on the way back from Delaware.

Air Tank

3/4" NPT elbow Male-Female

3/4" female ball valve

3/4" male to 1/2" female NPT reducer

1/2" male NPT to 1/2" barb

1/2" hose

1/2 male NPT to 1/2" barb

Air dryer (1/2" female NPT inlet and 3/4" female outlet)

3/4" NPT male to 3/4" socket

3/4" tube

3/4" coupler

3/4" tube

1" to 3/4" reducer elbow

1" Copper Tubing

1" Elbow at ceiling

1" Tubing

Tee at ceiling ->

LegA

1" tubing - 66"

1" to 1/2" reducer

1/2" tubing

1/2" Socket End x Female Pipe bronze casting

Parker quick disconnect

LegB

1" Tubing - 130"

1" Elbow

1" Tubing - 130"

1" to 1/2" reducer elbow

1/2" pipe

1/2" Union

1/2" pipe - 3"

1/2" NPT Male

Air Filter/Regulator

1/4" NPT Barb fitting

3/8" hose

3/8" NPT Barb fitting

90 deg 3/8 NPT Male-Female elbow

Harbor Freight 3/8" 50' hose reel

3/8" NPT Parker B23 quick coupler female (B23 for 1/4" NPT right now)

tubing hangers

Air Cooler

Compressor

5/8" tube?

?

1/2" NPT to 3/8" barb fitting

3/8" hose

Summit Transmission Cooler w/ Barb Fittings

3/8" hose

1/2" NPT male to 3/8" barb fitting

3/4" male to 1/2" female reducer

Air Tank

Posted by Z28tt at 7:58 PM | Comments (0)