|

|

|

|

This page is an ongoing diary of the Tufts Twin Turbo

Project and what we are doing to build a twin turbo 1989 Camaro. The IROC has a

smallblock chevy 350 cu. in. TPI engine that is currently putting out 320 hp. With the

turbo, I expect at least 450 hp at 8 lbs of boost and over 750 hp when the engine is built

to take 15-25 lbs of boost. This is an accepted official design project (ME 93)

as part of my mechanical engineering education at Tufts University. Some of the

requirements are genuine academic achievements, along with the experience of organizing a

complete project. Here are some of my ideas:

- Analyze the engine and determine efficiency and horsepower before and after the twin

turbos are installed

- Determine how much power the engine can safely produce without breaking. This includes

determining the cylinder pressures, autoignition points (detonation/knocking), compression

ratios, strength of materials in the engine, forces on engine components etc...

- Design the most efficient twin turbocharged exhaust and intake as possible.

Possibilities are scavenging headers, harmonic ram air induction (runner length

backpressure pulses force more air into heads) An intercooler might be a part of this.

- Do a cost/benefit analysis for this project.

The educational portion of the project has been completed, and now the challenge

continues. I am happy to announce that I received an A for this project. Countless people

have helped in the project with advice and experience. Job Spetter from Turbo People in

Hastings, NY, Mark Hamill from Accel/DFI, Mike Zoner from Callaway Cars, and the staff at

Turbonetics have been invaluable in the design phase of this project, and Professor

William Crochetiere at Tufts University assisted with my endless questions regarding

electronics and the Tufts Mechanical Engineering Department. Thank you to all the sponsors

who donated parts and offered a discount. Thanks to everyone that helped.

The basic turbo setup is complete, but the modifications

continue. All the weak points are being found and better replacements

are being installed. The 26 spline axles in the factory 10 bolt snapped in

November 2000, so the rear was replaced with a 35 spline spooled Ford

9" from Moser

Engineering. The Dynotech 3" Al driveshaft bent, and then

later the 1LE Aluminum Driveshaft was torn in half, so at least I

know the new rear and McLeod Street Twin clutch is holding. During the

winter of 2000, the front mount intercooler was completed, which included

a new tubular front bumper. The best timeslip so far is 12.82@113 on an 80

degree day with 5

psi boost on the factory L98. I plan on raising the boost to 10 psi soon.

Future plans are for a detonation-proof 355. 98+

LS1 front brakes are being installed as well as the Herb Adams decoupled

torque arm. I will try to get a dyno run before the L98 dies a spectacular

death. Keep watching the website for updates. We are averaging almost 100 hits a day

to the website. There is plenty here to read, and if you have any questions left, please

ask. |

|

|

|

|

|

Camaro Heaven Third Generation F-body Junkyard Call

1-800-Camaro-1 or email Chuck |

Spearco Intercoolers |

Magazine Coverage!!!

The Z28tt website was mentioned in the December 2002 Issue of

Popular Hot Rodding

Magazine

letters section. Thanks for writing in!

High Tech Performance

Magazine featured the

Z28TT website in the Cyber Cruisin' column in the March 1998 issue. Check out our review! (published

with permission of High Tech Performance) Website of the Month!!! We've been

featured in James O'Reilly's Camaro Website. This is one of the best looking Camaro sites

I've seen. professional artwork, and the layout is simple, yet very elegant. Take a look!

8/11/04 - Summer Update

It's been quite a while since the last update! The separate electrical ECM

panel is complete. When we went to fire up the new engine, we did not get

a reliable spark, which tested out to only be 5,000 volts (should have

been 40,000 volts). Even though the coil tested fine according to the

service manual procedures, it was replaced and all was well. The next

issue was low oil pressure, even with 15W50 break-in oil. We changed the

smallish Bosch filter for a large Fram HP4 racing filter, and pressure

jumped 15 psi. The small filter may have gotten clogged with the Redline

break-in grease. The Fram was replaced with a Wix 51062R racing filter and

Mobil One 15W40 oil after the break-in was complete at the National F-body

Event at Indianapolis Raceway Park this June. We attempted to tune the

air/fuel on the track, but it was much easier with a few miles of street

driving. Once the tune was in the ballpark, the Z28tt could actually be

raced! It was down since November of '01 from the wiring meltdown at

LimeRock, and now finally running. Life is good.

After the NFME event at IRP, there was an EMRA time trials on the Pocono North

course, using one of the banked NASCAR turns. The Z28tt handled pretty

well with the 950 lb front springs, 175 lb rear springs and Koni Yellows,

and was slightly tail happy, so I'll change down to a smaller 21mm rear

swaybar from the current 24mm bar. There is the 36mm hollow front bar on

there right now, and tires are old Kumho Victoracers (315's in the rear

and 275's up front). I did manage to get the 2nd fastest time of the day,

a 1:01.71, so I left home happy. The new issues with the extra cornering

is that I was getting oil starvation on all right hand corners, as well as

oil overheating (pegged the 300 deg Autometer gauge, so it was in the 340

degF range). I added an 3qt Accusump to the oiling system (I already have

a Canton pan), mounted behind the dash, a CM remote oil filter, and a

TruCool oil cooler between the radiator and intercooler. We'll see how

that works out at Watkins Glen next month.

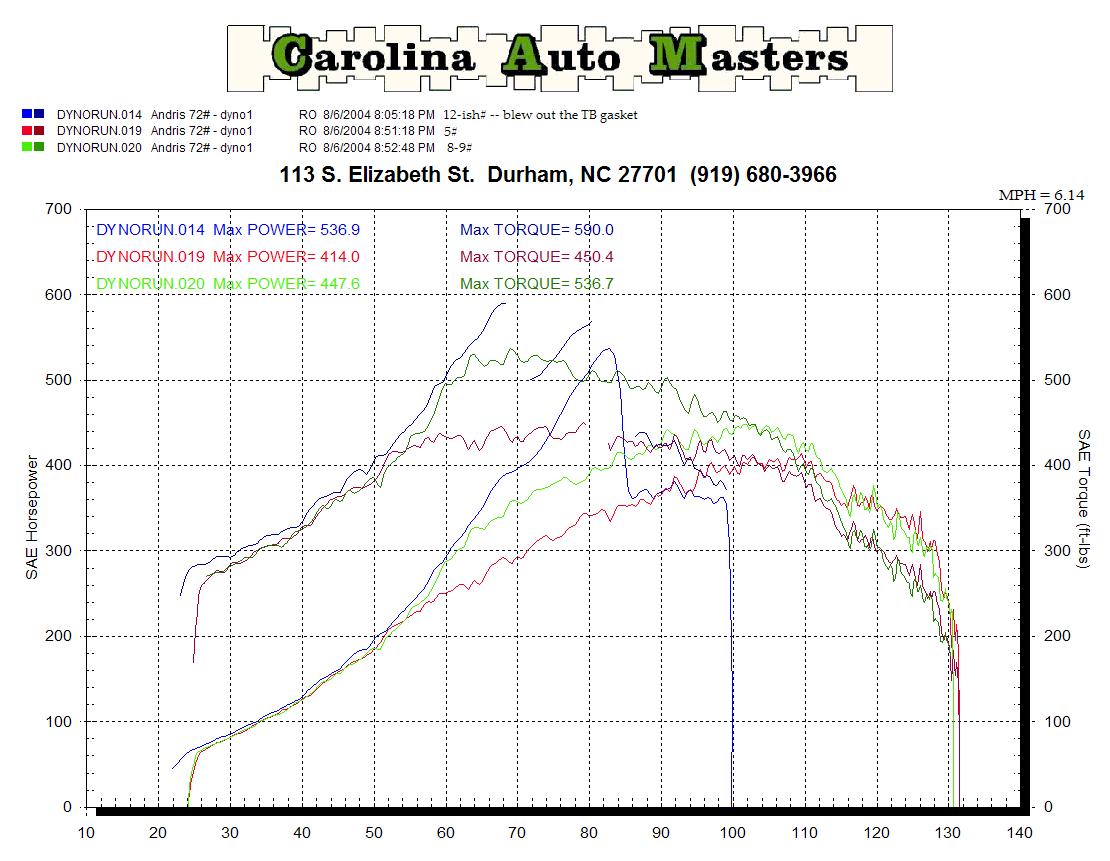

This past weekend I loaded up the Z28tt, and headed down to Durham, NC to

visit Jeff, John, and Pat at

Carolina Auto Masters for some dyno tuning. Over 2 days, we managed to

get 20 runs in, and played with various combinations. The existing tune

was decent, but very conservative on the timing (24 deg at 5 psi), so we

bumped that to 27 deg, and then again to 30 deg (not much change over 27

deg). Afterwards, we made a $1 boost controller with some brass barb

fittings, a tee, and a small ball valve. At 5 psi, we got 414 rwhp and 450

rwtq. The boost was turned up to 12 psi, and we got 447/536. Unfortunately

the boost started dropping off after 4k, possibly showing how restrictive

the 2.5" downpipes and 3" catback were. Just for curiousity, we

disconnected the wastegates completely. The boost climbed to 17 psi, and

then the spark was blown out by 3800 rpms. I guess the stock HEI ignition

(new plugs & .034 gap) just couldn't keep it lit. We did get 537/590 at

3800 rpms, though! I have the Accel 300+ wired in already, and will

disconnect the catback exhaust the next time I take the Z28tt to the dyno.

The guys at CAM were a big help getting all the testing done in just 2

evenings.

Finally, I stopped at Muscle

Motor Parts in Huntersville, NC to pick up a NASCAR exhaust, with the

flat side pipes (boom tubes). This will be fabricated into a 3" dual

exhaust, from the turbos back, most likely this winter, and should take

care of the backpressure problem.

EmailAndris Skulte